Porcelain FAQS

We cut through the current porcelain hype and try to provide the facts, with the most important considerations and best advice for your project, especially for porcelain paving jointing, which is crucial for success in installation, and long-term durability in service.

There is a lot of information and misinformation about porcelain paving that is now available online, as well as in the sales brochures from Tile Manufacturers, Paving Stone Distributors, Garden Centres and Builders Merchants (the operative word probably being ‘Sales’!), - Not to mention the sales pitches from all the various salesmen. External porcelain paving is on trend in the UK, and so suddenly – Everybody is a Porcelain Expert!

The information on these pages is provided in the following sections if you want to scroll to your specific area of interest, or you can read through to be fully aware before you buy anything anywhere – Good luck!

1. What is Porcelain & How are Porcelain Tiles Produced?

- Advantages of External Porcelain Tile Paving

2. Porcelain Tile Paving Performance Characteristics

- Cleaning and Sealing Porcelain Paving

- Porcelain Paving Slip Resistance

- Porcelain Paving Cleaning and Jet-washing

3. Successful Porcelain Paving Installation

- Substructure & Bedding

- External Porcelain Tile Paving Jointing / Grouting

4. Porcelain Paving Jointing – Using GftK's vdw 815+ and vdw 850+

1. What is Porcelain & How are Porcelain Tiles Produced?

Porcelain is a specific type of ceramic material that is made using very fine clays, with the addition of very finely ground and graded sands, plus quantities of the mineral feldspar, which are also added into the mix. This is forcibly sieved and combined in powerful compulsory shear mixing equipment, to produce a uniquely smooth and homogeneous base mix with a uniform consistence, which can be adapted and formed through pressure moulding and extrusion processes to make many different porcelain products. These can range from the traditional Chinese hand-made, top quality, almost see through, porcelain china for the best tea services, through high-tech electrically insulating porcelain components for many specialist areas in the power production and transmission industries, to porcelain floor and wall tiles, which now includes external porcelain tile paving. Today, porcelain ceramic components and surfaces are produced in specialist plants all around the world, and these are used for countless different applications in many different production and processing industries, where ultra-smooth, dense, hygienic, insulated and temperature resistant elements and surfaces are required. Porcelain tiles are one example where the concept of hard, stain and scratch resistant, easily cleaned surfaces is increasingly attractive, including to many people in the UK as one of the hottest trends for domestic patios and terraces.

Porcelain tiles are produced by moulding the specially produced porcelain ceramic mixture over a cheaper conventional clay ceramic base mix, and these layers are then fired together (heated quickly) at higher temperatures (~1400°C) than are generally used for most ceramic tiles (~1150°C). This results in porcelain ceramic tiles with a surface that is far denser, less absorbent and more abrasion resistant than normal ceramic tiles. These renowned positive material characteristics can also now be combined with recent technical advances that make it possible to print virtually any colours and images into the porcelain surfaces, allowing for almost unlimited design possibilities and effects with almost unlimited colours, to photographic images in the surface making the paving closely imitate all types of natural wood, natural stone, or pretty much anything else you can imagine, without many of the original materials limitations – What’s not to like….?!?

Advantages of External Porcelain Tile Paving:

External grade porcelain tile paving is also growing in popularity due to the almost unlimited range of paving unit shapes and sizes that can be factory produced and quality controlled, making even more designs possible, as well as having the virtually unlimited colour range and image imprinting that seems to expand and widen every month e.g. from porcelain tile s with mosaics, to timber planks, even including weathered driftwood or cut bamboo!

In fact with porcelain tile paving you can have the appearance of whatever you and your Architect / Landscaper can imagine!

As a result of all these properties and advantages, external porcelain tile paving is a great addition to modern hard landscaping options. The use of porcelain tiles is growing rapidly for many domestic paving applications at a tremendous rate, year on year, and all over the UK, especially for high-end domestic patios, terraces, and pool surrounds. However, for fast and successful installation, followed by good durability with years of service, just as with all types of paving, it is important to understand the product characteristics and be aware of its limitations e.g. when selecting the right paving jointing system for external porcelain tiled surfaces - This is because using the right jointing material is important for successful installation, and critical a long service-life. External porcelain paving is usually laid with narrow joints, typically 3-5 or 5-8mm is recommended, depending on the tiles size, and narrow joint widths also increases the importance of using the right jointing material to achieve durable results! To assist your decision making process and help ensure the selection of the best material for jointing on your porcelain project, we discuss and outline the best approach for the grout selection and then pointing external porcelain tiles, in more detail below on this page – Any questions or concerns then you can also email us for more specific porcelain support: sales@nccstreetscape.co.uk or call our Customer service team on 01257 266696 for their FREE Expert Advice.

2. Porcelain Tile Paving Performance Characteristics

Whilst porcelain tile paving can have tremendous potential and advantages, with this rapidly increasing trend towards using porcelain in the last few years, we have also seen that some of the positive characteristics have sometimes been exaggerated or taken a little too literally shall we say! Therefore it is probably good at this point in our dissertation to note and review some of the key performance characteristics – and todate we have heard all the following ‘characteristics’ individually or more usually combined, as the ‘reason’ people have originally decided to use porcelain tile paving:

“We are using porcelain tiles for our paving project because they are non-slip and do not need cleaning as they are washed clean in the rain and….

- …… Red wine spills will not stain it!

- …… BBQ fats, oils, grease, and foodstuffs will not mark it!

- …… Bird droppings can be brushed-off!

- …… Algae, moss, and other green growths, leaf and grass stains will just wipe-off!

Really…. Good luck with all of this …!?! Porcelain to paving is therefore the universal panacea and answer to the maiden’s prayer then……?

No seriously though, much of this is, or at least can be, more-or-less true - BUT not always, and it is always a question of degree and must be considered with common sense and sensible limitations!

Let’s have a look at each of these Performance Characteristics and hopefully explain:

Firstly, the facts-of-life are that like any outdoor surfaces, external porcelain tile paving will always need a good cleaning and maintenance regime and depending on the specific porcelain surface profile / texture and its exposure, the surfaces may also benefit from additional surface protection and sealing on site. We always advise caution in making external porcelain tile paving performance in service assumptions, because as always and again as with all types of paving, there are other important factors to be considered. So, we find that this is really a question of the level and relative ease of staining and/or ease of cleaning specific porcelain surfaces in different specific situations and exposure in different specific environments. For sure, all dense, highly fired, porcelain ceramic surfaces are going to resist staining and be far easier to clean than porous sandstone paving for example, but this may only be comparable with properly sealed sandstone or granite paving. This is always going to be a question of the type, extent, and scale of spillages, and like all exposed external horizontal surfaces, all types of porcelain tile will require regular if not frequent cleaning, and they may require some form of additional protection at sometimes, according to the exposure. For example, appropriate additional protection / sealing can make porcelain surfaces much more resistant to staining and easier to clean after spillages – horses for courses!

Cleaning and Sealing Porcelain Paving

Unfortunately, some people only find this out when their new porcelain tile paving, including their porcelain paving grout, is stained, and their porcelain surfaces seem to need frequent cleaning to keep their attractive appearance. This can be a difficult time for everyone involved, including the patio owner, paving contractor, tile merchant, tile manufacturer and lastly but not least!) the paving grout manufacturer – Everyone can get dragged into time-consuming debate and argument that is always best avoided. This is best done from the beginning of the process - In practical terms, porcelain tile paving is much like any other external paving and hard landscaping surfaces, as these all need to be installed correctly and then kept clean with an appropriate regime established, to keep the surfaces in prime condition for the best long-term performance and aesthetics. Fortunately, NCC have extensive experience, expertise and have invested in the research and development of the best materials to help you do this most easily, successfully and cost effectively, right from the beginning, with all types of paving and especially porcelain tile paving.

On the more detailed Paving Cleaning and Paving Sealing pages of this website there is a lot more information on products developed specifically to clean and protect all types of paving, as well as some special products that are designed specifically for external porcelain tile paved surfaces. All these products are also available from this website in our Online Shop Products specifically designed for external porcelain tile paving include:

- NCC Porcelain Cleaner - Aftercare - Porcelain Cleaner - Aftercare is designed to make porcelain tile surfaces faster and easier to cleaning and to be used frequently for regular Aftercare.

- NCC Porcelain Intensive Cleaner – As it says on the tin – for the Porcelain Intensive Cleaner is designed for the intensive cleaning of porcelain tiles surfaces after heavy soiling, and/or at the end and the beginning of the annual ‘alfresco’ season for example - Whenever that is in the UK!

- NCC Porcelain Protector – As it says on the tin – Porcelain Protector is a specially developed external porcelain tile surface sealer, which can be applied prior to the initial tile grouting (see below) operations, or after thorough cleaning at any time, where this protects the surfaces by increasing resistance to future staining and making cleaning easier.

Note: We should probably also say here, amidst what are not meant to be demeaning comments about porcelain paving, as we do believe that handled correctly, external grade porcelain tile paving is a fantastic addition to the landscaper’s options, and it is ideal for many domestic patios, terraces, and pathways.

Porcelain Paving Slip Resistance

Well yes it can be, especially when tested to the International, and mostly European (read German) Test Standards and test procedures that are now generally used as the basis for such statements. These standards are also widely used for many other types of floor coverings, from vinyl sheeting to resin flooring and even carpets and ceramics, including porcelain tiles – BUT as clearly stated, most of these test procedures were and are intended as INTERNAL FLOOR tests i.e. for floor covering materials used indoors and for ‘shod’ feet (wearing shoes), whilst barefoot testing, such as for use around swimming pools is something else again, take a look at the tile profiles near your local public pools – hmmmmm?

There doesn’t seem to be any standardised test for this form of surface when used outdoors. However, notwithstanding this, the results of these tests and the classifications received by specific porcelain tiles, can be a very good guide to their potential slip and skid resistance. BUT their actual slip resistance performance will almost equally depend on the interaction of other important aspects including any slope, the type and extent of spillages, the nature of any footwear and the type of activities in the area e.g. running is always more risky!

Slip resistance measurement and standards

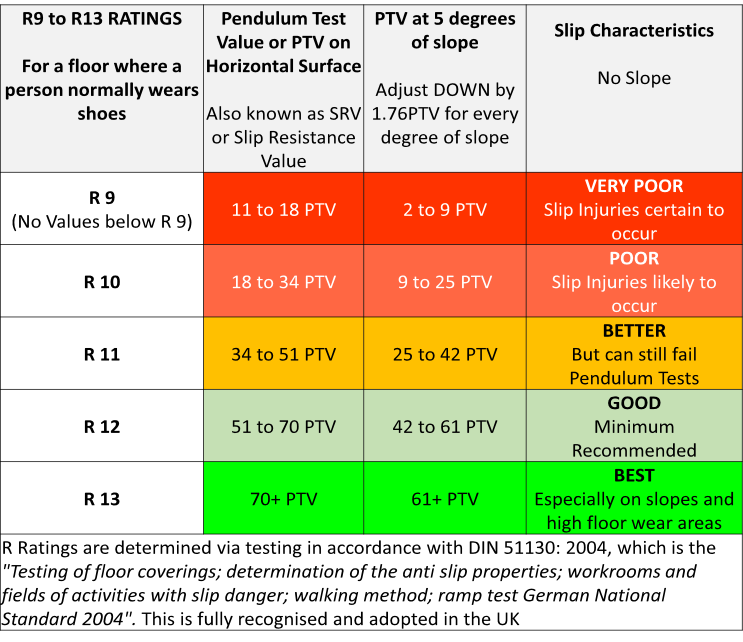

The commonly referred to R ratings relate to the typically non portable DIN Standard Floor RAMP Test for Shod Feet, where the ‘R’ relates to the ‘R’ in Ramp Test This basically works by floor samples being fixed to a ramp and then oil is applied on to it, whilst the ramp is raised and then the trained test technician walks in small steps backwards and forwards wearing boots until they slip on the floor. The computerised readout then determines the R ratings for the floor surface based on the angle of slip. Note - the values start at R9 which is the LOWEST slip resistance and R Rating (NOT R1 as you would think – no one seems to know why…?); the R Ratings then progress through increasing values of resistance to the HIGHEST floor slip resistance at R13, the highest slip resistance achievable in the test.

’ABC’ Ratings for BARE FEET must conform to DIN 51097. ABC Ratings are used for wet floor conditions where bare feet are the norm such as saunas, Jacuzzis, public showers, swimming pools etc.

German standards DIN 51130 and stipulate an ‘R rating’. These tests involve a person walking up and down a ramp where the surface is the test floor contaminated with oil whilst the angle of inclination is increased. The results are given in a range (starting for no good reason we know) at Class R9 - Most likely to be slippery, and they go up to Class R13 – the least likely to be slippery - BUT - When the surface is wet and/or contaminated with spillages, and outdoors – Don’t bank on it!

So in summary – Yes - Porcelain Tile Paving can be slip resistant, but please use common sense – All and any external paved surfaces, using porcelain, natural stone, or concrete, can and will be slippery and therefore dangerous in some situations, and especially when wet and/or contaminated with any other spillages – especially any oils and greases, where dense porcelain maybe more slippery as none is absorbed into the surface, therefore increasing the risk of slips and falls! Common sense is required!

Porcelain Paving Cleaning and Jet-washing

Porcelain paving does not need cleaning e.g. by jet-washing……? Well maybe, BUT ONLY if you keep it pristine clean and treat the porcelain paved surfaces like you do your indoor floors, where you would normally remove and completely clear-up any spillages immediately. Plus, again as you would do indoors, you ensure that the porcelain paved surfaces are swept and mopped clean at least once a week or so, according to use, and that this cleaning regime continues throughout the year, EVERY WEEK of the year and NOT JUST IN SUMMER! – Otherwise, you will find it necessary to jet wash your new porcelain tile paved surfaces regularly, if not frequently, but it will be advisable to do so several times every year as a minimum, to keep it clean and looking good! This will certainly be necessary at the start & end of the season, as well as after any days of heavy use and/or spillages!

As YOU WILL need to jet wash your porcelain tile paved surfaces, please be sure to point the tiles with a paving grout / paving jointing mortar that can withstand this direct jet-washing treatment and will not wash-out! As mentioned, and explained in more detail elsewhere on this website, NONE OF THE 1-part, air-drying, vacuum packed ‘resins’, bag-in-a-tub products, so-called ‘resins, or ‘brush-ins’, paving joint compounds etc., are suitable for porcelain tile paving in the long term. Not even GftK’s own Patio grout or vsw 840+, as none of this type of product can fully / adequately resist direct jet-washing - There are many brands widely available in most merchants; they may seem relatively cheap and very easy to apply - BUT - They will cause you problems with your nice new porcelain paving – and usually sooner rather than later, so all these compounds are best avoided - Even gftK’s Patio grout, which is tested and proven to be the best 1-prt, air-drying, paving joint mortar. BUT it will not take direct jet-washing for very long. Why on earth would you want to select expensive porcelain tile paving, and then use the cheapest ‘brush-in resin’ or tile grout available from in the local Garden Centre, Stone or Builders Merchant – Or from anywhere come to that……!

3. Successful Porcelain Paving Installation

Substructure & Bedding

There is a lot of useful advice and information available from many sources in the UK, on the use and installation of external porcelain paving, so this is not our focus. For assistance we recommend the UK’s only fully independent source of natural stone and concrete paving information, which has extensive information on the correct installation of all types of paving in the UK, with special sections on external porcelain tile paving. This is the excellent www.pavingexpert.com/porcelain-paving.

A word of caution: beware of similar named website imitations of this still superb trade advice site, which have more recently created by Online merchants trying to cash-in on the original www.PavingExpert.com ‘brand’ and the name of the late great Tony MacCormack, and which unfortunately the internet does not yet police properly!

The suggestion that porcelain tile grouts must be totally impermeable when laid on full concrete beds rather than consolidated granite chippings as prevails in Italy for example, is also a bit of a ‘red herring’. This is explained in detail by an excellent article by the paving expert Tony McCormack at www.pavingexpert.com In principle this is a red herring and irrelevant because porcelain tiles should be laid to falls of 1 in 60, like honed sandstone paving, which is because this is very smooth and ‘polished, so it is very slippery when wet, as well as being very porous and easily stained unless it is sealed – ideally before installation or grouting. Therefore, this is also much higher for external porcelain than the falls of 1 in 80, normally used for most natural stone and concrete paving. The reason is again, to prevent water and water borne dirt and residues standing or ‘ponding’ on the surface, increasing the risk of staining and the other sort of falls, slips and trips etc. This increased fall ensures fast surface water run-off into the drainage system. Additionally the now established UK method of laying porcelain with an SBR or proprietary bonding slurry on the backside, laid directly into a full wet mortar bed, also prevents any possible theoretical water underflow, along the bondline, as this is now impermeable and watertight. In any event, as of May 2022, in the records of the PavingExpert, there is absolutely no evidence of any sub surface freeze-thaw damage to paved surfaces anywhere throughout the vast majority of the UK. The substructure and bedding used for external porcelain tiles is therefore normally much the same as for most other types of quality ceramic and natural stone paving, e.g. in requiring a sound substructure to take the anticipated load, a suitable bedding mortar, and then using an SBR Slurry Bonding bridge ‘wet-on-wet’ to ensure the secure bedding of porcelain paving tiles. However, the jointing of external porcelain requires special consideration due to the nature of this material, and we have tried to outline below in an evaluation of the available options for you to consider (or not!):

External Porcelain Tile Paving Jointing / Grouting:

There are two keys to the long-term success in the jointing (also called grouting or pointing – same thing) for external porcelain tile paving - the material must provide relative Ease of Installation to prevent errors and unnecessary additional work on site, and then the jointing material itself must be stain resistant and able to withstand water-jet cleaning to have the necessary long-term performance for Durability in Service.

1. Ease of Installation: For external porcelain tiles it is essential to always use an equally high-performance jointing material. This means not only selecting jointing that is easy and fast to apply, including in the variable British weather conditions, with showers and rain in the forecast much of the time. It also makes sense to use a non-staining paving joint mortar one with minimal requirements for cleaning the residues, or residual haze from the porcelain surfaces.

2. Durability in Service: As mentioned above regarding the need to frequently clean porcelain surfaces, which will inevitably involve jet-washing sooner or later,, it is sensible to select a jointing mortar that will stand up to frequent jet washing. Unfortunately, ALL of the 1-component, air-drying, paving joint mortars (also often called brush-ins, or vacuum packed, bag-in-a-pail types or 1-part ‘resin’ jointing compounds etc., are just not durable enough to be recommended for the long-term grouting of external porcelain tile paving.

In the UK today, porcelain paving jointing is still carried out with all available material options, including from site batched sand and cement, to pre-bagged cement paving joint mortars, plus various forms of tile gout 9good for indoors, but because it is waterproof it does not make it suitable for outdoor use with UV exposure and thermal movement to cope with. Then there are all the 1-part, air-drying compounds now widely available on the market, plus high performance, 2-part, epoxy resin based joint mortars.

So, there are many different technologies, types of material and brands of products used for external porcelain tile jointing, though unfortunately many of these are being oversold and / or recommended for this application, which in reality, is at or beyond their limitations. We will explore and explain this on the pages of this website. It is also perhaps unfortunate, or at least a factor in these issues, that external porcelain paving is a relatively new and recently burgeoning trend in the UK, which has grown out of all proportion to other paving systems in the last 5 years, especially since the lockdown paving boom from 2020 to 2021. As a result, much of the market experience for owners and their contractors, is still relatively new, as it is for paving distributors and stone merchants, now seeing external porcelain tiles make up a very significant part of their business, with the problems and issues with using the wrong jointing material for external porcelain paving just starting to appear. This includes issues arising for professional paving contractors and DIY owners, many believing they have done a good job, now faces with everything from porcelain surfaces that seem impossible to clean after grouting, specifically with cement based mortars, porcelain surfaces that seem to get stained easily, as well as the biggest problem of the joints failing, either by crumbling, by cracking and breaking up in normal service, or being blown out and removed during normal jet wash cleaning operations.

In NCC Group we understand and supply all available paving joint technologies, and we can therefore give unbiased and independent advice on the best technologies to use in each situation for new and remedial works. Therefore, in these pages we have tried to give a balanced view and summary of theses different paving joint technologies and materials, with a detailed assessment of their respective characteristics, performance, and limitations. For full details please see the Paving Jointing pages of this website. However, the following is a brief summary, specifically in relation to their use with external porcelain tile paving:

Brush-in Jointing Compounds for porcelain - There are many different brands of these 1-part, ready-to-use, air-drying, paving jointing compounds, such as Geofix, one of the earliest on the market in the 90’s, followed by others such as SikaFix and in recent years EasyJoint and then Joint-it, which have all been heavily marketed and widely used across the UK, including for external porcelain tile paving. However, today nearly all brands of these materials, do not generally recommend their use for porcelain, including the highest performance products on the market GftK vdw 840+ and GftK’s Patio grout, which we supply. This is because, whilst any of the one-component brush-in ‘resin’ paving grout products may well go in easily to the narrow joints generally used for most external porcelain tile joints (e.g. from 3- 6mm wide), but then they will also come out easily too! In many instances, this will be within a disappointingly short time, especially with any direct jet-washing that they cannot fully resist. These materials are also very porous and can easily stain, with food and drink spillages, or grass and plantstuffs dropped and left on the surface, as well as being very susceptible to discolouring with green algae and organic growths. The permeability combined with low cohesive strengths, also means that such 1-part jointing materials are also not resistant to freeze-thaw damage and can break-up in the event of frost. Therefore even the best of these materials such as GftK’s Patio Grout, would likely only last a few years in external porcelain paving – So once again we always ask the question: “Why would you use this type of jointing compound in between expensive and generally professionally installed porcelain tiles….?” Some owners and contractors might think they are an easy solution as at least one variant of these is sold in very garden centre, stone and builders’ merchant, so they are widely available, cheap, and easy to install, sold as a universal panacea …………However, this would seem to be Madness to us! – We do not even recommend our own Patio Grout for these applications, and this is the highest performance 1-part, air-drying paving joint product on the market. Additionally a lot part ‘resin’ brush-in jointing compounds contain linseed oil and other ingredients that darken and stain natural stone, and they also tend to leave a haze over the porcelain surfaces, which can also be difficult and time-consuming, and therefore expensive, to remove after installation. So, …..Why would you do it…? Best avoid one part, air-drying, paving joint compounds for porcelain paving!

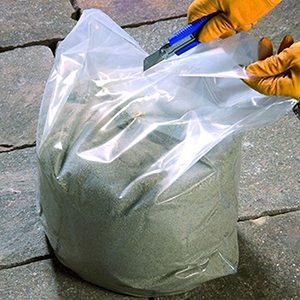

External cement-based paving grouts / jointing mortars are considered suitable for external porcelain and indeed they are widely used throughout the UK, BUT these are also not ideal, as like all cement mortars they have some poor performance characteristics. This also includes the recent crop of so-called, hybrid cement-based grouting mortars - ‘hybrid’ in this context is just a bit of ‘Marketing-Speak’ for some products, which simply means that they have a bit of polymer added as a plasticiser, which ALL prebagged, cement based, paving jointing mortars now do to reduce their natural tendency to shrinkage and cracking! However, these are still cement, hybrid-polymer-modified or whatever, with all the advantages of cement products such as low cost and high compressive strength a low permeability, but unfortunately, they also have disadvantages in relation to paving jointing and specifically to porcelain! Indoor cement tile grouts are not sufficiently durable for long term external exposure i.e. they lack flexibility and crack due to the wider outdoor temperature variations and thermal cycling e.g. from the sun; cement-based grout will also stain easily with typical patio spillages such as red wine and BBQ foodstuffs on patios and terraces. Cement based paving jointing systems used for external stone paving, including porcelain, generally has more cement with graded sands, made smooth and flowable with plasticizing polymers. Unfortunately the key weakness outside is residual water in the joints or washing down or sudden rainfall, which destroys the carefully designed water to cement mix ratio, and this will lead to cracks on site, maybe only visible after a few days and the contractor has been paid and moved on! There is also the issue that in any event, any dense substrates, so especially like porcelain, will have only limited adhesion to cement mortars and so once again, this makes shrinkage cracking and debonding due to normal thermal movement likely over a relatively short time, particularly at the top of the joints – which is of course, the last place you want any cracks!

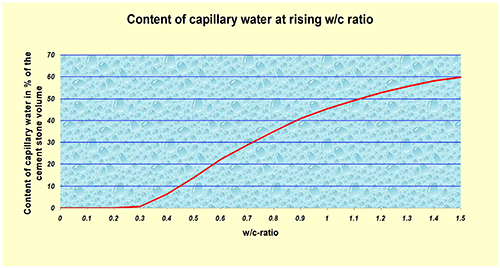

2-component, epoxy resin based, resin bound paving jointing mortars: The best and most technically sound solution for good quality, high performance, external grade porcelain paving jointing in our experience, is a high performance, 2-part, epoxy resin bound, graded fine alluvial sand based jointing system. This unique technical solution is provided by using the most appropriate GftK Paving Joint Mortar according to the porcelain tile joint widths i.e. 2-part, epoxy resin based, GftK vdw 815+ or GftK vdw 850+, for joint widths from >3mm or >5mm respectively, which are undoubtedly the best we have seen for durable external porcelain tile jointing / pointing., without cracking issues. Cement style shrinkage cracking is always a ‘none-issue’ with GftK’s 2-part, vdw range of epoxy resin jointing products. The only permeability related issue for the UK, only happens with 1-part, vacuum packed paving joint compounds; as these will quickly discolour and allow algae and other green growths to collect in the pores and as they cannot be jet-washed and cleaning chemical discolour them, the green discoloration cannot be removed – another reason to avoid this type of inferior products for quality porcelain paving!

4. Porcelain Paving Jointing – Using GftK's vdw 815+ and vdw 850+

GftK's vdw 815 and 850 Paving Joint Mortars are unique, 2-component, epoxy resin based, materials that is designed for durable sealing of narrow joints, making it ideal for grouting porcelain paving with joint widths from 3mm, though the normally recommended spacing for larger format external porcelain tiles is 5-8mm to avoid edge issues. When grouting newly laid porcelain after the tiles are firmly bonded in position and strong enough to walk on, the surface must always be rinsed clean and then dried. This is also an opportune time to protect the pristine surface against future staining and resides for building works. This is done by applying NCC Porcelain Tile Protector and allowing this to dry, prior to the grouting operation. As the video shows, mix the 2-components of the GftK vdw 815+ together thoroughly until the mix is fully homogeneous, which should be for around 3 minutes. Pre-wet the paving and then pour out the vdw 815+ as shown, using more water to help it flow into the joints, you can't use too much water at this time. Continue moving the mortar with a rubber squeegee as it effectively self-compacts into the joints. Once filed leave for a few minutes and then use a wet coconut brush to remove any excess, using more water in a fine wide spray as required to remove any residual material and clean the surface. Job done!

To help ensure success with your project, on the Case Studies & Video Application Guides page of this website there is a recent Project Case Study and Application Guide for grouting external porcelain tile paving joints with vdw 815+, plus pre-sealing the tiles with NCC Porcelain Protector. This video is also available to view on the NCC Streetscape YouTube Channel here: https://www.youtube.com/watch?v=2exywKqYN0k&t=19s

Call NCC Streetscape and, use the GftK vdw 815+ or GftK vdw 850+ solutions to get it right first time - and for the long term!

For more advice or assistance with your specific porcelain tile paving project:

- To Select the best jointing product use our Product Section Guide.

- To Estimate the quantity of material required use our Paving Joint Consumption Calculator.

You can also email us for more specific support: sales@nccstreetscape.co.uk and you can call our Customer service team during normal office hours, on 01257 266696 for FREE Expert Advice.