Air-drying, 1-part ‘Brush-ins’ / ‘Resins - Online Shop

These are all completely prebatched ‘Paving Jointing Compounds’, which were originally introduced some years ago in the UK, as ‘Wide Jointing Compounds’, likely after ‘Geofix – Wide Jointing Compound’, which one of the first successful branded products of this type. Today, these paving jointing materials are more commonly referred to as ‘Brush-ins’ or ‘Resin Compounds’, and technically, they are more correctly described as ‘One-part, air-drying, vacuum-packed, prebatched, jointing compounds.’ which are always supplied as ‘ready-to-use’ mortars, in vacuum-packed plastic bags, in a protective plastic pail. They generally consist of blended sand and other fine inert fillers, mixed with an acrylic polymer dispersion and other additives. The ready mixed polymeric sand mortar is supplied in a sealed bag that is vacuum-packed to prevent premature evaporation of the water content, which is the hardening mechanism of the products. This is also why the hardened mortars are permeable with capillaries left by the water evaporation, which in turn also determines that these materials should only be used on a permeable substructure to prevent water-logging and damage of the jointing material. In domestic patio paving this is generally not a problem, as there is a limited substructure build-up required for these anticipated loadings, and the bedding mortar for most domestic paving is generally also permeable, typically a 1 to 5-6 cement to sharp sand mix is used.

Air-drying, 1-part, polymeric sand paving joint mortars, supplied in vacuum-packed bags in pails

For application, the pail is opened, the sealed bag is taken out, cut open, and the premixed, ready-to-use product is simply poured onto the paved surface, which is usually prewetted to reduce absorption and prevent staining, then the material is brushed, or wet-slurry applied, over and across the surface and into the joints, usually with more water according to the manufacturer’s instructions. Most of these products are then ‘tooled’ down to ensure compaction into the joints, using a special pointing tool or fine trowel. However, the latest high-performance developments of this type of jointing technology do not require this additional tooling down, as they can be effectively wet-slurry applied and are self-compacting into the joints, which also minimises cleaning and saves considerable time, as well as reducing the weather limitations of most 1-part paving jointing compounds (e.g. GftK’s Patio Grout. After a few minutes for excess water to evaporate and joints to initially set, any residual material on the paved surfaces is brushed and rinsed-off, then the surfaces are allowed to set and fully dry by evaporation. For all these products this should be for a minimum of 24 hours before any walking on the area to prevent damage to the material, though at lower temperatures (i.e. 5⁰ C to 15 ⁰C), then this waiting time should be longer, as the hardening process may take several days. These materials are generally easy to use, and they can work very well, but only for non-trafficked surfaces of domestic paving – As with ALL paving jointing materials, in addition to their positive characteristics of ease of use and relatively low cost, these products also have several important limitations, as well as only being suitable for use on paving with a permeable bed i.e. they are normally only for domestic paving.

-

Open the pail & cut open the vacuum-packed bag

-

The mortar is supplied ready to use, just pour directly onto the prewetted paved surface

-

Use a squeegee or brush, and more water, to move across the surface and into the joints

-

Ensure the joints are filled, brush 7 rinse off any residue

Note: Cheaper, widely available, air-drying products may also require additional tooling and topping up, unlike the ‘Best-in-Class’ vacuum-packed air-drying products from GftK that are self-compacting, which gives better performance in service – See below for strength and performance comparisons.

Note: These compounds are also frequently, but quite wrongly, referred to as ‘Resin Jointing Compounds, which is very confusing as they are nothing like the advanced 2-part Resin Paving Joint Mortars, such as those from GftK, which are detailed and described outlined elsewhere on this website.

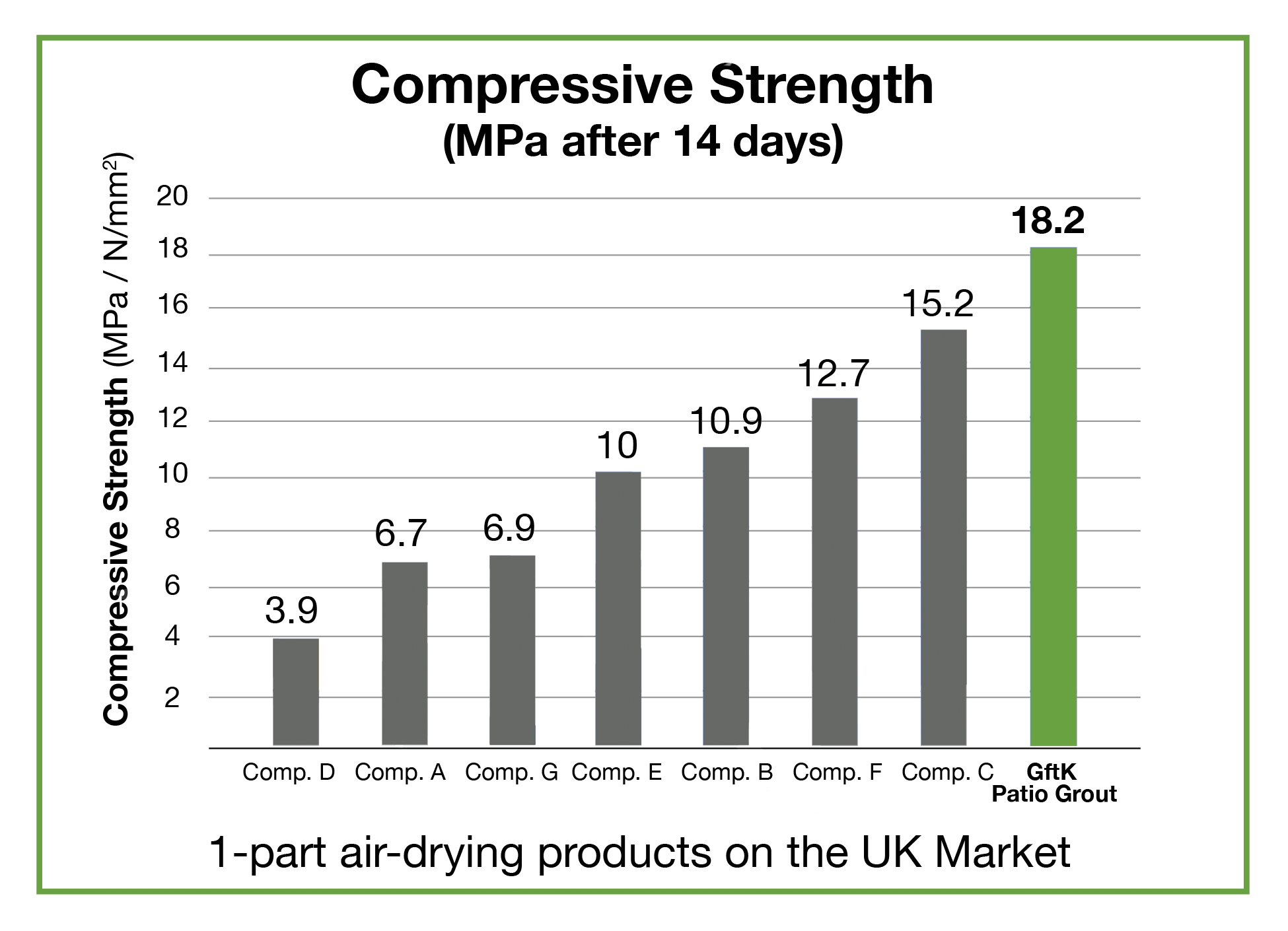

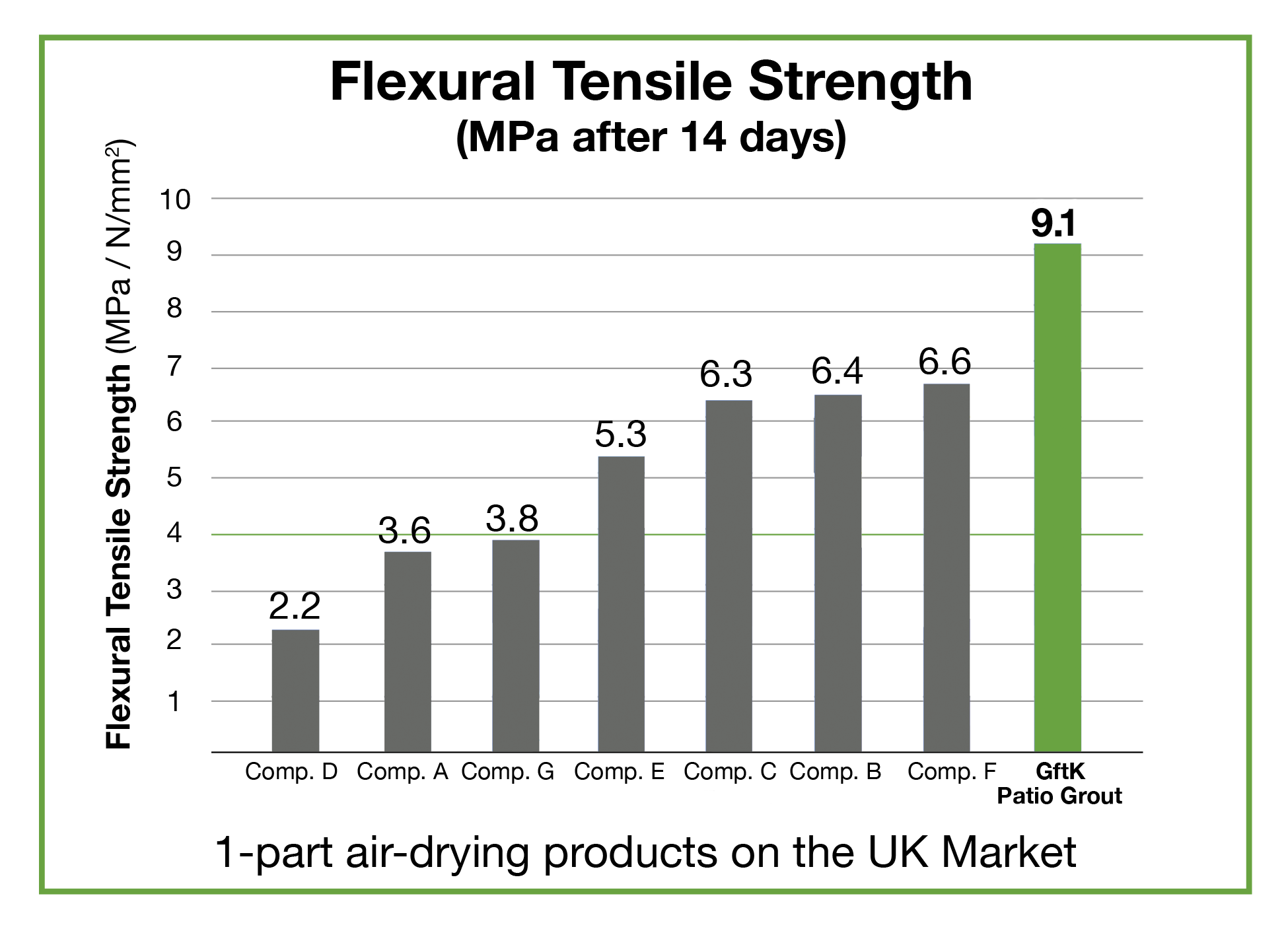

Additional limitations of this type of paving jointing compound, include relatively low strengths and e-modulus, meaning they should not be used for paved surfaces subject to static or dynamic vehicle loadings, i.e., they are not suitable for trafficked paved surfaces such as driveways and parking areas, plus their low strengths also mean that they have very limited resistance to pressure jet washing.

However, many of these polymeric sand based, paving jointing compounds, are now widely available in many different brands from almost every Builders Merchant and Garden centre in the country, as well as paving centres and online etc., and so they are very widely used by DIY customers and General Builders alike. This is not only because they are widely available, but also because they are quick and easy to apply, giving a reasonable finish. However, they are used much less often by specialist paving contractors, groundworkers and civil engineering contractors, due to their focus on areas with heavier loadings and where they have been used in civil engineering applications and trafficked surfaces the one-part paving jointing compounds have inadequate strengths, resistance and durability.

However, many of these polymeric sand based, paving jointing compounds, are now widely available in many different brands from almost every Builders Merchant and Garden centre in the country, as well as paving centres and online etc., and so they are very widely used by DIY customers and General Builders alike. This is not only because they are widely available, but also because they are quick and easy to apply, giving a reasonable finish. However, they are used much less often by specialist paving contractors, groundworkers and civil engineering contractors, due to their focus on areas with heavier loadings and where they have been used in civil engineering applications and trafficked surfaces the one-part paving jointing compounds have inadequate strengths, resistance and durability.

or your patio at home, they can be great, especially if you select the latest technology in 1-part, air-drying, vacuum-packed paving jointing, of which the best on the market and ‘Best-in-Class’ is undoubtedly tested and proven to be:

GftK’s vdw 840plus-

Retro-designed ‘Crazy paving’ ready for prewetting & jointing with GftK vdw 840plus

-

Crazy paving patio completed with DIY jointing using GftK vdw 840plus

-

Designer paving sculpture with GftK vdw 840plus

-

Sandstone patio jointed with GftK vdw 840plus in Basalt

and the latest version of this innovative technology for the UK:

GftK’s Patio Grout-

Simply open the pail and cut open the bag of GftK Patio Grout

-

Wet-slurry apply the GftK Patio Grout with a squeegee and spray hose

-

Rinse the paved surface with clean water using a light spray

-

Finally brush-off any residue – Job Done!

Selecting the Right Paving Jointing Materials Technology & Product

As outlined above and on the other pages of this website, there is no universal paving jointing materials technology and no universal paving jointing product. The right paving jointing for your project depends on the key criteria and your specific requirements.

We have produced a Paving Jointing Project Checklist, which is designed to help you identify and confirm all the relevant selection criteria for each project, in terms of the type and size of area, paving, joints, the site for installation and the required exposure and performance in service, durability, cleaning regime, plus the ease of closure and ease of eventual repointing.

We have also produced the GftK Paving Jointing Product Selection Guide that you can use this with the Checklist for each project, to ensure you consider all revenant criteria and select the most appropriate paving jointing solution. Always be sure to consider ALL the key criteria and parameters for your paving project, to make the right technical and commercial decisions based on ALL the requirements.

For more advice or assistance with your specific paving project, please call 01257 266696 for FREE Expert Advice during normal office hours, or you can email us at any time to: sales@nccstreetscape.co.uk and we will get back to you just as soon as we can. Thank you.