Cement-based Paving Joint Materials - Online Shop

Cement-based paving joint materials are probably the widest paving jointing materials category with many different types and methods of application, and they all use the advantages of cement technology, whilst they are also all constrained by cement technology. The main advantages of cement-based jointing are relatively low cost, wide local availability, variable mix designs and multiple options for application, achieving high compressive strengths and load carrying capability. The main disadvantages of cement-based jointing materials, include the moisture sensitivity of the fresh mortars, limitations of the weather for application and curing, then the risks of staining and additional cleaning demands, as well as the performance issues with the potential for subsequent shrinkage cracking, as well as limited flexibility (tensile flexural strengths) for thermal movement accommodation. Cement-based paving jointing materials include traditional hand trowel pointing with site-batched sand and cement, as well as many product formulations with special cements and additives, such as polymer-modifiers to increase performance (e.g. increased flow with reduced water cement ratio etc.), which are generally factory produced and pre-batched for greater quality control.

High performance, high quality, wet slurry applied, coloured, cement based paving joint mortar - GftK vdw 400plus Color - The 'Best-in-Class

Roman Road across Rishworth Moor, near Manchester

As outlined elsewhere on this website, various forms of cement-based paving jointing have been carried out with great success and durability for around 6000 years, since the original development of ‘cements’ by the Minoans, the Greeks, the Romans, and every civilisation since. The key advantages of sand and cement has also always been that these materials are relatively cheap and widely available, especially for site-batching. However, there are also several disadvantages in using cement-based materials for paving jointing works, which can be significant as mentioned above, but whilst the risk of cement staining and the additional surface cleaning works, which are always necessary after using any cement jointing, were not important building major roads and highways to connect the Roman, or indeed the British Empire, they can be hugely significant and must be avoided for the paving on Mrs Smith’s new Patio and Mr Jones new sett Driveway!

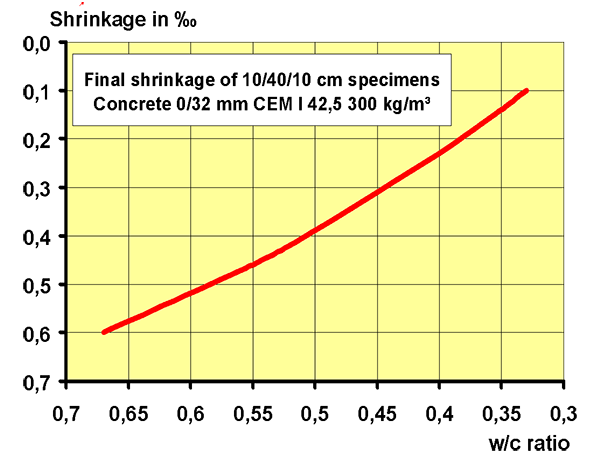

Also, not so widely understood, but very importantly for durability, all cement materials shrink due to hydration as they harden, and this can easily result in cracks at the surfaces or at the bond interface with the paving elements. This type of ‘initial shrinkage’ in cement-based paving jointing materials, is known as short-term ‘plastic shrinkage’, and this is due to the physical water loss from the freshly placed mortar by absorption into the substrate, or by evaporation into the air. The amount of plastic shrinkage in a cement mortar is largely controlled by the water to cement ratio, which must be kept to the optimum levels of around 0.3 to 0.5, because over 0.6 to 0.8 the amount of shrinkage cracking increases dramatically, as clearly shown in the graphic below.

Also, not so widely understood, but very importantly for durability, all cement materials shrink due to hydration as they harden, and this can easily result in cracks at the surfaces or at the bond interface with the paving elements. This type of ‘initial shrinkage’ in cement-based paving jointing materials, is known as short-term ‘plastic shrinkage’, and this is due to the physical water loss from the freshly placed mortar by absorption into the substrate, or by evaporation into the air. The amount of plastic shrinkage in a cement mortar is largely controlled by the water to cement ratio, which must be kept to the optimum levels of around 0.3 to 0.5, because over 0.6 to 0.8 the amount of shrinkage cracking increases dramatically, as clearly shown in the graphic below.

It is for this reason that there must be strict control of the water cement ratio on site and there must be no free-standing water in the joints, or this will severely disrupt the product mix design and the lab test results on datasheets become meaningless! This is why experienced concrete technicians talk about ‘Lab-crete’ and Site-crete’ as distinct variations of all types of ‘Con-crete’. There can be a very big difference in cement-based materials hydration shrinkage, cracking, and their subsequent performance properties, especially when the water cement ratios are not strictly controlled, especially if there is excess water added in to the mix during the first few hours, during mixing, application and curing / hardening.

It is for this reason that there must be strict control of the water cement ratio on site and there must be no free-standing water in the joints, or this will severely disrupt the product mix design and the lab test results on datasheets become meaningless! This is why experienced concrete technicians talk about ‘Lab-crete’ and Site-crete’ as distinct variations of all types of ‘Con-crete’. There can be a very big difference in cement-based materials hydration shrinkage, cracking, and their subsequent performance properties, especially when the water cement ratios are not strictly controlled, especially if there is excess water added in to the mix during the first few hours, during mixing, application and curing / hardening.

Note: Cement mortars can also experience longer-term shrinkage cracking, due to further cross-linking in the complex cement hydration and chemical reactions, as well as physical drying shrinkage over time, though long-term shrinkage is not a significant issue for paving jointing.

This is the primary reason that for the last 25-35 years or so, to try and reduce / counteract these shrinkage effects, and enhance overall performance, cement-based paving jointing / pointing mixes have generally been ‘polymer-modified’ (PM) in some way. This means that they have an additional ingredient in the mix, which is generally added on site as a liquid ‘polymer’ dispersion, such as Styrene Butadiene Rubber ( SBR) or Acrylic Copolymers (Vinyl’s), which can easily be added to site-batched paving and pointing mixes. Alternatively, for prebagged, prebatched, powder products produced in a factory, freeze-dried polymers are used and blended into the cement and dried sand/aggregate/powder fillers. This liquid or powder polymer addition, increases wet mortar flow, workability and compaction etc., for easier application, plus it allows less cement to be used, and with a lower water to cement ratio, which in turn also improves the performance and durability of the hardened mortar in the joints. These improvements in characteristics and performance are technically achieved because the polymer reduces the capillary sizes and overall volume, which reduces the rate of water evaporation, improving hydration and strengths, and with reduced shrinkage cracking – Polymer addition inclusion in cement-based paving joint mortars, is therefore a ‘win-win-win’ combination. Today the most widely used freeze-dried polymer admixtures are polycarboxylate (PCE) copolymers, which have been derived from high performance concrete superplasticiser technology. In laboratory testing and under ideal site conditions, i.e., where the water content is strictly controlled, these polymer-modified paving joint mortars perform extremely well and can have minimal or even zero shrinkage cracking.

HOWEVER, despite it being necessary to strictly control water in the mix with all cement-based paving jointing products, it is also always necessary to pre-wet and dampen the substrates, ideally to an ‘SSD’ (Saturated Surface Dry) condition, to help ensure a good bond, and to prevent water migration into the paving elements from the controlled / measured product mix material. This is because any significant additional water addition to the mixed mortars, such as excess, residual water remaining in the joints from the pre-wetting operation, then the cement mortar’s mix design that has been laboratory formulated, with an optimised water to cement ratio, is immediately and very significantly altered. This water addition and water cement ratio disruption, very adversely affects the mortar mix, negating almost all the performance stated on the product data sheet, or in the site mix design. As a result of this increase in water to cement ratio, there is a very significant increase in shrinkage and cracking of the jointing, depending on the amount of residual water present in relation to the cement mortar mix. So, for all cement based products strict control of the water cement ratio is essential, specifically, always check and blow out any standing residual water immediately before application of cement mortars, including slurries, then it is also important to use minimal additional water to help the flow during application, and also very importantly, use minimal water for cleaning operations, especially immediately after application and initial set, but also for the first few weeks. Any recommendations to remove cement staining by water jetting and/or any chemical treatments, must also be avoided for at least 28 days after installation. This is to ensure full hydration and curing to optimum joint mortar strengths and performance characteristics on the technical datasheets. The use of excess water for cleaning immediately after application will also cause surface efflorescence on the mortar surfaces which can be unsightly, especially with coloured cement mortars. So, once again ‘Buyer Beware’!

Damage and deterioration of the joints following shrinkage cracking, is by far the biggest cause of premature failure for all types and brands of cement-based paving jointing products. However, this can be a difficult one to diagnose, as the very nature of this issue means that the initial cracks are formed at the time of the pointing/grouting/jointing works on site - BUT they may effectively be invisible or seem to be of no consequence at that time. The cracks become bigger and more visible over time following full hydration, and then normal cyclical exposure to weathering in service. The further issues arising from water ingress into these cracks, do not arise for some time, which can be for several months, or even several years depending on the paved areas environment and exposure. Typically, paving joint cement mortar shrinkage problems will always be more visible and evident after winter, when water penetration and freeze-thaw reaction at low temperatures takes place and causes physical damage. The main reasons for this are usually that the original paving was of good quality, BUT for the paving joints, cement-based materials were used in bad weather conditions and led to the premature joint failure.

Water to cement ratio disruption will take place whenever any free water / residual moisture is present in the joints, such as from pre-wetting the paving, from earlier cleaning works, from recent rainfall, or run-off onto the newly grouted paved area. So once again it is always important to remember that cement-based paving jointing materials can have great advantages and are easy and fast to apply, but it is also important to understand the limitations, especially relating to their water to cement ratio with additional water before during and immediately after their application water!

These damaging effects are also greatly accelerated by use of de-icing salts on paved areas, so this typically happens on public roads and pavements, but this also creates jointing issues for public car parks, and domestic driveways, with the salt brought in on the cars. As evidence of this issue, you will see many areas of prematurely failing cement-based joints in paved surfaces in the street and around salt treated public and commercial areas. Frequently, you will find that there are many visible patch repairs to the paving, and areas where the jointing is cracked and/or breaking up.

Note: The modern, wet-slurry applied, polymer modified, cement-based, paving jointing mortars can resist de-icing salt exposure extremely well, BUT, when shrinkage cracks due to the water cement ratio being disrupted during application, then premature failure will still occur!

Water Cement Ratio Problems with Cementitious Jointing

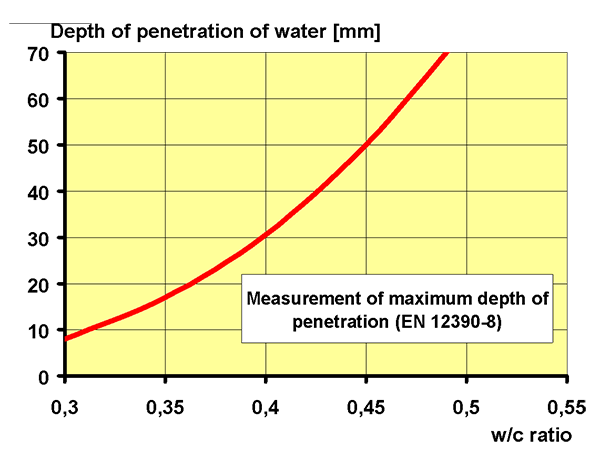

As outlined above, perhaps the key limitation and potential issue with any cement based paving joint mortar, be it traditional site-batched or a factory pre-batched product, is preventing exposure and interaction with residual or added water in the joints during installation and/or during the initial phases of setting and hardening. This water can be from the necessary prewetting, from any water addition to improve flow, or from the surface cleaning operations; as well as from any pre-, or immediately post-application, rainfall, cleaning, or any water run-off from adjacent surfaces. Wherever any excess water comes from, it will always have seriously negative effects on the water cement ratio of the product / design mix, because the increased water cement ratio will change and significantly reduce the hydration process, increasing shrinkage and cracking, then reducing the hardened performance and durability of all cement-based paving joint mortars. This increased risk of both short- and long-term shrinkage cracking, can be by up to a factor of x 3, - 300% or more, plus there can be an even more dramatic increase in the hardened joint mortar capillary content, by up to a factor of x 6 – 600% or more. The result in practice is reduced performance and durability of hardened cement based paving joint mortars, due to significantly reduced resistance to water ingress, increased permeability to water borne de-icing salts, which leads to increased frost damage, plus the mortars will have much lower strengths that on the products respective Technical Datasheets and Test Reports, which are all based on tightly controlled water and water cement ratio in the laboratory. Therefore, in situ the materials will have much lower strengths and resistance to load, stress exposure and cleaning regimes.

Figure 1. Cement Mortar Shrinkage vs Water : Cement Ratio

Figure 2. Cement Mortar Porosity (as Penetration) vs Water : Cement Ratio

These two graphics are well known in cement technology and used to Illustrate the dramatic changes that occur when the water cement ratio of a cement-based mortar is changed, just as it happens in the real-world joints on site.

- As can be seen in the first graph: Through the addition of any additional free water locally or along the whole joint, there can easily be 300% more shrinkage that will cause significant cracking (short and long-term), during curing and hardening of the product / design mix, than when precisely tested prebatched in a laboratory for the respective Product Data Sheets and/or any ‘Test Reports’, i.e. these are totally theoretical values and the real world is different.

- In the second graph: This graphic shows that with additional water, the hardened cement-based mortar, will be anything up to 600% more permeable / porous than the intended mix design in the controlled laboratory test samples. Therefore, with this lower hardened density and much higher pore / capillary network in the cement matrix, the mortar will have much lower strengths and be very much weaker, with a severe loss of tensile / flexural strength. As a result, the joints will be far more permeable and susceptible to frost damage from freeze-thaw attack and de-icing salts, as well as being more likely to stain and far less resistant to both natural erosion and modern cleaning regimes, especially jet washing and mechanical street cleaning machines.

These important differences are the reason that engineers can refer to Concrete as ‘Lab-Crete’ or ‘Site-Crete’ – These can be very different in performance when the environmental conditions for application are not ideal, which is never easy with the great British weather. Another thing to bear in mind is that defects and damage from this shrinkage and increased permeability may not be immediately apparent, because these damaging effects may take some time to develop and a couple of winters to show – But this damage happened at the time of the jointing material’s application.

Surface Cleaning after Cement-based Grouting

All cement based paving joint mortars have the potential to stain porous and sensitive stone surfaces and can leave a ‘cement haze’ on many other types of paving, including porcelain that is difficult to remove. There is also the additional risk to the integrity of cement-based jointing and all the issues of water cement ratio disruption by the cleaning processes, particularly if large amounts of water and/or water-jet cleaning is carried out before the jointing mortar has fully cured and completely hardened. Typically this will also cause efflorescence on the mortar surfaces as well, which is not great for coloured cement mortars, though it will disappear over time with normal exposure weathering, but customers may not be happy! Therefore, it is always best to avoid washing and any jet washing of newly cement mortar grouted paving until the mortar has fully cured and hardened, typically this should always be at least 28 days at 20 °C, so longer in cooler temperatures. Once again, it is a case of Buyer – Beware!

The Choice of Paving Pointing Technology and Products is Yours!

Can you control the environment and after treatment sufficiently for the next month or so, to ensure the correct application and curing of cement-based paving jointing mortar……?

If so, then these are a great and very cost-effective solution. If not, then you will be faced with awfully expensive repointing or worse, and within a few years or sooner. For signs of this just look around any public or commercial paved areas where the decision on the pointing mortar was likely made for a cement-based product, and decided largely on the initial cost, or worse, on the cost per 25 kg pack, instead of on the specific project requirements, site conditions and the overall durability for a long-term sustainable solution.

Traditional stone sett paving was typically pointed with a 3-4 to 1, cement to sand, site batched mix, made and hand trowel applied by trained and experienced craftsmen in small quantities, working on their hands and knees. The paving was then carefully cured correctly under damp hessian for a week or more at least, plus they did not do this work when it was cold and wet, or hot and dry. However, the cost and time pressures on all forms of construction nowadays, mean that larger areas of paving are jointed with cement-based jointing, tend to be installed by wet-slurry techniques, sometimes also with pumped delivery of these very fluid mixes, and then after initial set, the surfaces are cleaned with damp sponges and even mechanically cleaned to remove remaining cement residues. Though, once again this is also sensitive to environmental conditions, especially temperature and humidity.

As some variation of water to cement ratio is almost inevitable with whatever method of cement pointing on any UK paving project, there will always be some risk and some inherent defects installed from the beginning. This is not to mention the issues of inadequate curing and protection of cement mortars from direct sun and winds that cause the next biggest problem of excess evaporation. This can also result in the loss of surface strength and increased permeability, as well as cracks in cement paving joint mortars – though these will not be seen at the time, they come back to cause latent defects after a relatively short peri od of time.

Cement based paving joint mortars can also have issues with joints that have variable dimensions (i.e. when the joint width and depth varies significantly along the joints), which as with all thin layer cement-based mortars and concretes, creates variable stresses within the material during hydration, and even in the correct environmental curing conditions and mix ratios, this can also lead to increased shrinkage and subsequent cracking. Therefore, generally a cement-based paving jointing mortar should only be used for uniform paving joint dimensions, meaning they are often not ideal for repointing works.

Cement-based mortars adhere most tenaciously to roughened, permeable mineral surfaces, whilst their adhesion to smooth impermeable surfaces such as metals, plastics and ceramics, including porcelain tile edges, is much lower and therefore generally not ideal for stress transfer or accommodating any form of movement, including for thermal variations. This should also be a consideration for larger areas of exposed paving, where some form of movement accommodating joints may also be required, rather than a cementitious material. This is also the reason that elastic joint sealants are used to create ‘movement’ or ‘expansion’ joints in larger concrete and brickwork structures. The effects of expansion and contraction caused by thermal movement in the structure must be accommodated by joints with a higher movement capability.

Cement-based Paving Joint Mortars – Summary

In summary, it may seem that on this page we have focussed on the disadvantages and limitations of cement -based products for paving jointing, but we must also stress that cement-based paving jointing in many different forms, has and does provide a highly effective solution in many hard-landscaping situations. In fact, cement based paving jointing is used for somewhere over 80-85% of all paving joints in the UK, when you look across all sectors (domestic, commercial and public areas including highways etc.), though more in some markets and applications, such as those subject to heavier loads and on larger projects, so this type of material is certainly not all bad. Indeed, GftK also develop, produce and market high performance cement based paving jointing materials, including GftK vdw 400plus Color – the ‘Best-in-class, wet-slurry applied, coloured, cement-based paving jointing on the market!

GftK vdw 400plus Color

-

Tools & equipment, ready to apply GftK vdw 400plus Color

-

Wet-slurry Pointing with GftK vdw 400plus Color

-

Wet-slurry application of cement-based, GftK vdw 400plus Color

-

Completed, high-end, porcelain patio, jointed with GftK vdw 400plus Color

Selecting the Right Paving Jointing Materials Technology & Product

As outlined above and on the other pages of this website, there is no universal paving jointing materials technology and no universal paving jointing product. The right paving jointing for your project depends on the key criteria and your specific requirements.

We have produced a Paving Jointing Project Checklist, which is designed to help you identify and confirm all the relevant selection criteria for each project, in terms of the type and size of area, paving, joints, the site for installation and the required exposure and performance in service, durability, cleaning regime, plus the ease of closure and ease of eventual repointing.

We have also produced the GftK Paving Jointing Product Selection Guide that you can use this with the Checklist for each project, to ensure you consider all revenant criteria and select the most appropriate paving jointing solution. Always be sure to consider ALL the key criteria and parameters for your paving project, to make the right technical and commercial decisions based on ALL the requirements.

For more advice or assistance with your specific paving project, please call 01257 266696 for FREE Expert Advice during normal office hours, or you can email us at any time to: sales@nccstreetscape.co.uk and we will get back to you just as soon as we can. Thank you.